|

| |

Motorized Goniometer Stage

|

|

Home

>

Motorized Goniometer Stages

|

|

|

|

|

|

Stepper Motor Driven

Goniometer Stage

|

Three Phase Brushless Servo Motor with Quadrature Incremental

Optical Encoder Driven

Linear Goniometer Stage

|

|

|

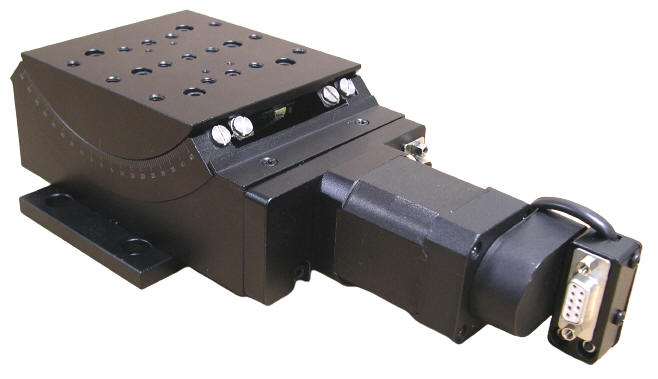

The

AK120-45

Goniometer

Series

features

precision

ground

worm

gears

with

a

296:1

ratio

and

pre-loaded

cross

roller

guides,

and

+/-

45

degrees

of

travel

with

10

kg

of

load.

The

very

high

resolution

of

0.0006

degrees

(2.16

Arcsec.)

is

realized

when

using

the

standard

Two-Phase

Stepper

Motor

driven

by a

10

micro-steps

per

step

micro-stepping

driver

or

with

the

Servo

Motor

options

and

Quadrature

Optical

Encoders.

.

The

AK120-45

Series

of

goniometer

stages

feature

four

motor

options.

The

-01

option

is

Stepper

Motor

driven.

The

-02

option

(pictured)

is

driven

by a

Three-Phase

Brushless

Servo

Motor

with

a

Quadrature

Optical

Encoder,

the

-03

version

is

DC

Brushed

Servo

Motor

Driven

with

a

Quadrature

Optical

Encoder,

and

the

-04

option

is

Stepper

Motor

Driven

with

the

knob

replaced

with

a

Quadrature

Optical

Encoder

for

position

verification.

The

highest

resolutions,

accuracy,

and

travel

speeds

are

achieved

with

the

servo

motor

options

-02

and

-03.

This

AK120-45

Goniometer

Series

of

Stages

has

a

large

104

mm

long

by

90

mm

wide

table

with

a

precision

pattern

of

mounting

holes

for

precise

location

of

fixtures.

The

height

of

rotation

is

40.5

mm

above

the

surface

of

the

table

and

the

radius

of

rotation

is

67

mm

making

them

ideal

for:

Microscopy,

crystallography,

measurement

of

surgical

cutting

blades,

laser

positioning,

light

measurement,

and

inspection

applications.

This stage requires a

Motion Controller

that can be ordered as a complete plug-and-play system with RS-232, USB, joystick and keypad control.

Video Demonstration

|

|

Specifications

|

Type

|

AK120-45

|

|

Range of Travel |

+/-45 Deg |

|

Table Size |

104 mm x 90 mm

|

|

Gear Ratio |

1 Deg (stage) : 296 Deg (motor) |

|

Height of Rotation Stage |

40.5 mm |

|

Radius of Rotation Stage |

67 mm |

|

Drive Mechanism |

Worm Gear |

|

Travel Guide

|

Crossed-roller Guide |

|

Base Material

|

Aluminum Alloy |

|

Stepper Motor

|

| Typical Phase Current |

1 Amp |

|

DB-9 Male Connector

|

|

Pin Assignment and Description

|

| 1 |

+5 VDC for the Limit Sensors |

| 2 |

CW Limit Switch, Open Collector, Normally Open, Needs Pull up Resistor (1000 Ohms)

|

| 3 |

CCW Limit Switch, Open Collector, Normally Open, Needs Pull up Resistor (1000 Ohms)

|

| 4 |

Return for+5 VDC

|

|

5

|

Not Connected

|

|

6

|

Stepper Motor Phase A+ |

| 7 |

Stepper Motor Phase A- |

| 8 |

Stepper Motor Phase B+ |

| 9 |

Stepper Motor Phase B- |

|

|

|

|

Load Capacity |

10 kg

|

|

Weight

|

2.44 kg (5.5 lb)

|

|

Resolution |

Stepper Motor Driver or Servo Motor Optical Encoder Dependent

approximately 0.0006 Degrees (10 micro-steps per step or 500 Line per Revolution Encoder)

|

|

Maximum Speed |

7 Deg/sec |

|

Typical Positioning Accuracy |

0.05 Degrees |

|

Typical Positioning Repeatability |

+/- 0.01 Degrees |

|

|

|

Ordering

Information

|

Part No.

|

Description

|

Amount

|

|

AK120-45-01

|

Stepper Motor Driven Goniometer Stage,

|

Click to Get a Quote

|

|

AK120-45-02

|

Three Phase Brushless Servo Motor with Quadrature Incremental

Optical Encoder Driven Goniometer Stage,

Table Size 104 X 90 mm

|

Click to Get a Quote

|

|

AK120-45-03

|

DC Servo Motor with Quadrature Incremental Optical Encoder

Driven Goniometer Stage,

Table Size 104 X 90 mm

|

Click to Get a Quote

|

|

AK120-45-04

|

Stepper Motor Driven Goniometer Stage

with 500 Cycles per Revolution Quadrature Optical Encoder

Mounted at the back of the Stepper Motor

,

Table Size 104 X 90 mm

|

Click to Get a Quote

|

|

Related Products

|