|

| |

XY-theta Alignment Stage

|

|

Home

>

XY-theta Alignment Stages

|

|

|

The

XYR-50-100

Motorized XY-theta Stage is a high resolution, low profile, high load capacity, horizontal stage that can be easily integrated into any current or future application.

The precision ground screws provide 2.16 in x 2.16 in (50 mm x 50 mm) of travel in XY plane with high resolution and repeatability. The theta (rotary) axis range of travel is

+/-180 Degrees.

Some applications for the three-axis alignment stage include: testing, inspection, assembly and sampling in a broad range of industrial, medical, semiconductor and research facilities.

The stage is equipped with stepper motors. The X and Y axes incorporate the positive and negative limit switches. The rotary stage incorporates a HOME (INDEX) switch.

The rotary stage is also available with servo motor.

A solid core version is also available.

This stage requires a

Motion Controller

that can be ordered as a complete plug-and-play system with RS-232, USB, joystick and keypad control.

|

Part No.

.

|

Table

Diameter (mm)

|

Gear Ratio

|

Range of Travel

|

Load Capacity (kg)

|

Weight

(kg)

|

|

X

|

Y

|

θ

|

X (mm)

|

Y (mm)

|

θ (Deg)

|

|

XYR-50-100

|

100

|

1 mm per Motor Revolution

|

1

mm

per Motor Revolution

|

2 Deg per Motor Revolution

|

50

|

50

|

360 Continuous

|

9

|

5.9 |

|

|

Type

|

XY Plane

|

|

Structure

Description

|

Range of Travel

|

50 mm X 50 mm

|

|

Table Diameter

|

100 mm

|

|

Actuator Type

|

Lead Screw (

1 mm per turn

)

|

|

Travel Guide

|

Precision V-groove & Crossed Roller

|

|

Motor

|

Two Phase Stepper Motor (1.8 Deg)

|

|

Base Material

|

Aluminum Alloy

|

|

Surface Treatment

|

Black Anodized

|

|

Load Capacity

|

9 kg

|

|

Typical Accuracy

Description

|

Resolution

|

5 microns (Full Step)

0.12 5microns (20 Micro-steps per Step Motor Driver in use) |

|

Repeatability

|

1.5 microns

|

|

Positional Accuracy

|

5 microns

|

|

Accessories

Description

|

|

Servo Motor

Optical Encoder

|

|

Type

|

Rotary axis

|

|

Structure Description

|

Range of Travel |

360 Degrees |

| Stage Diameter |

100 mm

|

|

Through Hole Diameter

|

30 mm (Optional)

|

| Gear Ratio |

180:1 |

| Drive Mechanism |

Worm Gear

|

| Travel Guide |

Bearing |

| |

|

|

Base Material

|

Aluminum Alloy |

|

Surface Treatment

|

Black Anodized |

|

Typical Accuracy

|

|

Resolution

|

0.001 Degrees = 3.6 arcsec (10 Micro-steps per Step Motor Driver in use) |

| |

|

|

Maximum Speed with Stepper Motor

|

12 Degrees per second |

|

Maximum Speed with Servo Motor

|

45 Degrees per second |

| Positional Accuracy |

0.05 Degrees |

|

Repeatability

|

+/-0.01 Degrees

|

Electrical Connection

Two-Phase Stepper Motor (1.8 Deg) Typical Phase Current: 1.0 Amp

DB-9

Male Connector

,

X and Y axes

|

Pin No.

|

Description

|

|

1 |

+5 VDC for the Limit Sensors |

|

2 |

CCW Limit Switch

The table moves away from the motor

The knob turns counter clockwise

Open Collector

Normally Open

Needs Pull up Resistor (typically 1000 Ohms)

|

|

3 |

CW Limit Switch

The table moves towards the motor

The knob turns clockwise

Open Collector

Normally Open

Needs Pull up Resistor (typically 1000 Ohms)

|

|

4 |

Return for+5 VDC

|

|

5 |

Not Connected

|

|

6 |

Stepper Motor Phase A+ |

|

7 |

Stepper Motor Phase A- |

|

8 |

Stepper Motor Phase B+ |

|

9 |

Stepper Motor Phase B- |

DB-9

Male Connector

,

Rotary axis

|

Pin No.

|

Description

|

|

1 |

+5 VDC

Input

|

|

2 |

Not Connected

|

|

3 |

Not Connected

|

|

4 |

Common

|

|

5 |

HONE (INDEX) Signal

Open Collector

Normally Open

Needs Pull up Resistor (typically 1000 Ohms)

|

|

6 |

Stepper Motor Stepper Motor Phase A+ |

|

7 |

Stepper Motor Stepper Motor Phase A- |

|

8 |

Stepper Motor Stepper Motor Phase B+

|

|

9 |

Stepper Motor Stepper Motor Phase B- |

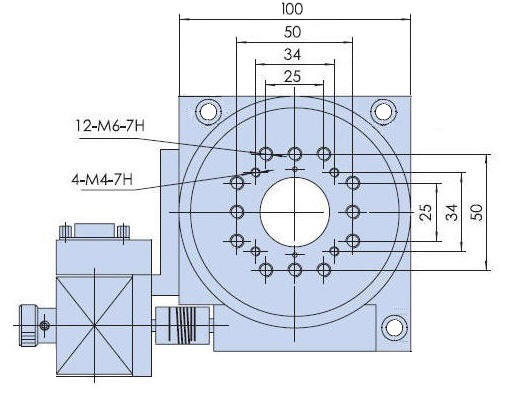

Rotary axis

Stepper Motor Driven Mechanical Drawing

- 100 mm

|

|

|

Ordering Information

|

Part No.

|

Description

|

Amount

|

|

XYR-50-100-01

|

Stepper Motor Driven

XY-Rotary Alignment Stage, Range of Travel,

X-axis 50 mm, Y-axis 50 mm, Rotary-axis 360 (Deg

Continuous

)

|

Click to Get a Quote

|

|

XYR-50-100-04

|

Stepper Motor Driven

XY-Rotary Alignment Stage

with 500 Cycles per Revolution Quadrature Optical Encoder Mounted at the

back of the Stepper Motor

, Range of Travel, X-axis 50 mm, Y-axis 50 mm, Rotary-axis 360 (Deg

Continuous

)

|

Click to Get a Quote

|

|

|